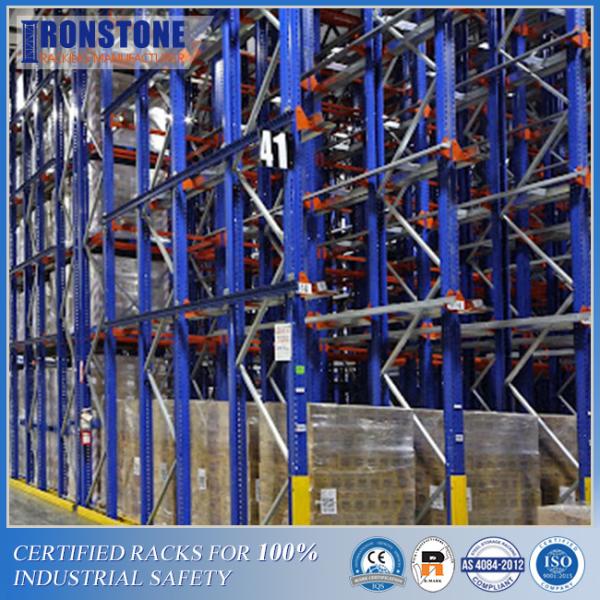

High-Density Drive In Drive Through Pallet Rack System for

Homogeneous Products

Drive-in pallet rack system is a high-density storage solution that

makes the best use of available space for storage by eliminating

extra working aisles. Every lane in the system is served as storing

space as well as an operating aisle for forklifts.

Drive-in pallet rack is made up of easy-to-assemble and

easy-to-reset modular structure, making it easy to maintain and

adjust to a new configuration.

In drive-in pallet rack system, one end is closed and forklifts

have to drive into and off the system through the same open end,

leading to LIFO storing and retrieving order. Besides, there is a

similar pallet rack system called drive-through pallet rack system

in which both end are open, and one is the entrance and the other

is used as exit. Thus, the first stored pallet can also be the

first one out that is FIFO order.

Drive in pallet rack system is an optimal choice for warehouses

with large volumes of homogeneous products for which selectivity is

not necessary but storage density is foremost.

Name | Drive-in pallet rack system |

Color | RAL color system, customized |

Loading Weight | 1000kg-2000kg per pallet, customized |

Material | Cold-rolled Steel |

Characteristic | First in-Last out(FILO) |

Standard accessories | Safety protectors, bolts, nuts, safety pin |

Components | Upright frame(upright, horizontal bracing, diagonal bracing),

beams, pallet rails |

Features of Drive-in Pallet Rack System:

- High-density storage, aisles are reduced for more storage space;

- First in, last out inventory management;

- Minimal investment, the structure is simple;

- Limited stock rotation, forklifts have to drive into the system for

storage and retrieval;

- Density is prior to selectivity;

- Suitable for storing a large number of homogeneous products that

are not time sensitive;

Material handling equipment: counterbalance forklift truck

Maintenance: Since forklift operators need to drive inside the racking system

directly, collision is prone to happen. Hence, it requires more

frequent inspection than other systems. The whole frame, anchors

and pallet rails are key points for the check.

Advantages of Drive-in Pallet Rack System:

- Provides certain product mixes with high storage density;

- Compared with other high-density storage solutions, the capital

investment is relatively low;

- Realizes efficient storage, since racks are aligned back to back

without aisles between them;

Limitations of Drive-in Pallet Rack System:

- Inflexible, does not allow for SKU increase

- Possible low storage utilization (typically 50% of positions used)

- Low productivity (30% slower than alternative systems)

- Requires standardized pallets

- Risk of rack damage by fork trucks

- Difficult to rotate time-sensitive products

Applications of Drive Pallet Rack System:

- Manufacturers with limited SKU counts

- Producers with limited product variation, date-segregated

production or batch production